Medical-grade hypodermic tubing (or needle tubing) poses some unique manufacturing challenges. Imagine maintaining precision while producing complex cuts and end shapes on micro tubes as small as 0.009” outer diameter…while simultaneously meeting all the strict requirements that come with modern medical manufacturing.

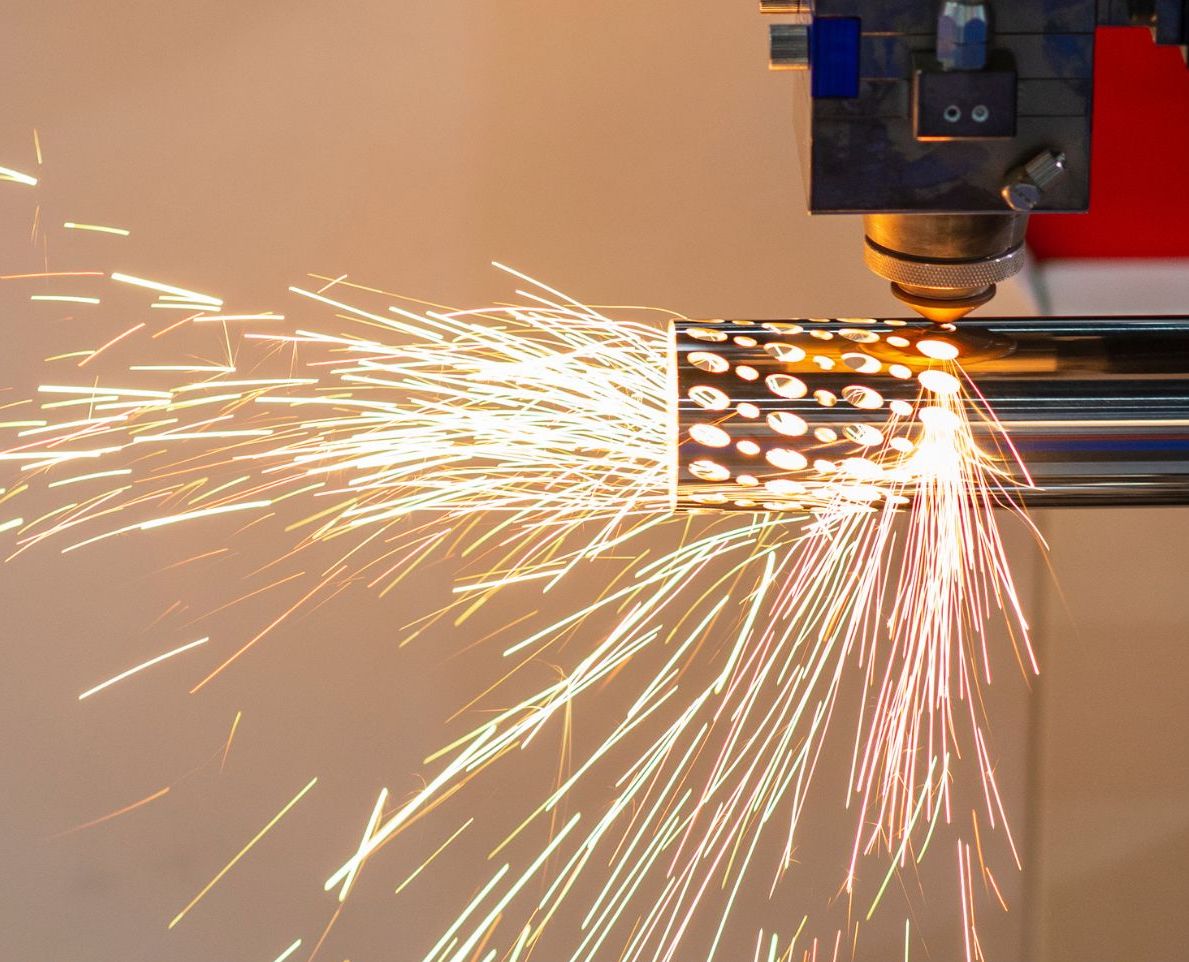

Luckily, compared to traditional machining methods, laser cutting has made the hypotube production process much easier, more accurate, and more repeatable. At HyTech Spring & Machine, we understand that such uncompromising repeatability isn’t just a specification, but the foundation of clinical performance.

Understanding Hypotubes: Complexity Beyond Traditional Medical Tubing

As everyone in the industry knows, hypotubes are far more than simple hollow tubes shrunken down in size. They’re in fact precisely engineered, complex components that must simultaneously satisfy multiple (often competing) performance requirements.

The fundamental challenge in hypotube design lies in balancing flexibility, torque transmission, pushability, kink resistance, and structural integrity into a single component. Unlike traditional braided or coiled reinforcement structures, laser-cut hypotubes achieve these characteristics through controlled material removal, creating intricate patterns that fundamentally alter how the tube behaves under clinical stress.

In many medical devices (catheters, stent delivery systems, minimally invasive surgical instruments), the hypotube serves as the device’s backbone. It must navigate complex anatomical pathways, transmit rotational force from the proximal handle to the distal tip with fidelity, withstand repeated bending cycles without kinking, and maintain its luminal integrity under compression.

Traditional mechanical machining methods struggle to achieve these requirements simultaneously, while our laser cutting systems are specifically suited to the unique challenges inherent in custom needle tube manufacturing.

Medical Laser Cutting: Superior Accuracy, Repeatability, and Processing

Achieving Micron-Level Tolerances

The most obvious technical advantage of laser cutting for hypotube manufacturing is unmatched dimensional precision. Modern laser systems, particularly fiber lasers, can achieve cutting accuracies of ±0.01 mm (10 microns) and, in advanced applications, down to ±0.005 mm (5 microns). This level of precision is essential because hypotube performance is fundamentally dependent on exact geometry.

Consider a stent delivery catheter where the outer diameter must maintain tolerances within ±0.005 mm and wall thickness within ±0.010 mm. Even minor deviations of a few microns can significantly impact device performance. For example, a wall thickness that’s slightly thicker than designed may reduce flexibility. If it’s slightly thinner, kink resistance suffers. With laser cutting, these tolerances are not merely achievable—they’re repeatable across thousands of parts without tool wear degradation.

Achieving Precision Tube Ends and Features

The precision advantage extends to feature creation. Laser systems can produce slot widths as narrow as 15 to 30 microns (0.015 to 0.030 mm), enabling intricate lattice patterns that would be impossible with conventional mechanical cutting. This fine-feature capability is critical for creating the complex geometric patterns that define hypotube performance characteristics.

Non-Contact Cutting Eliminates Mechanical Stress

Unlike conventional machining, where a physical cutting tool contacts the material under pressure, laser cutting is a non-contact process. A focused laser beam ablates or melts material without applying mechanical force. This fundamental difference delivers substantial technical advantages that directly impact component quality.

First, the elimination of mechanical stress prevents material deformation. In thin-walled hypotubes, particularly those made from sensitive materials like nitinol, mechanical cutting tools can cause localized crushing, deformation, or material flow that compromises structural integrity. The non-contact nature of laser cutting avoids this entirely, preserving the material’s original microstructure and mechanical properties.

Second, there is no tool wear. Conventional cutting tools gradually dull through repeated use, leading to degradation in cut quality and dimensional accuracy. Laser systems don’t experience this wear mechanism, ensuring that the first part cut maintains identical precision to the ten-thousandth part. This consistency is invaluable in medical device manufacturing, where regulatory requirements and patient safety demand absolute uniformity across production batches.

Minimizing Heat-Affected Zones

When metal is cut by any thermal process, the intense localized heating creates a heat-affected zone (HAZ) of the workpiece. The size and severity of the HAZ depend on how much heat is deposited into the material and how rapidly that heat dissipates.

In traditional laser systems, the HAZ can extend 50–100 microns or more from the cut edge, causing microstructural changes that may include grain growth, phase transformation, or hardness variation. For thin-walled hypotubes and sensitive materials like nitinol, this thermal damage can be catastrophic. Nitinol, in particular, derives its critical shape-memory and superelastic properties from precise austenite and martensite phase control. Thermal damage can shift transformation temperatures, reduce superelasticity, and compromise the device’s ability to recover from deformation.

HyTech’s laser cutting systems significantly reduce the HAZ of the workpiece compared to conventional machining methods. The result is better tolerance control, superior edge finishing, and compatibility with virtually any complex, customized needle tube design.

Maintaining Biocompatibility Through Precise Processing

Laser cutting maintains superior compatibility with sensitive medical materials. Stainless steel 304, 316, and 316L are common hypotube materials chosen for their biocompatibility, corrosion resistance, and mechanical properties. However, achieving proper surface finish and passivation is critical to ensure these materials remain biocompatible.

Laser cutting produces relatively smooth cut edges compared to mechanical methods, minimizing the need for aggressive deburring operations. However, even minimal HAZ residue and any recast material must be removed through secondary finishing. At HyTech, we combine laser cutting with electropolishing and controlled passivation to achieve surfaces that meet FDA biocompatibility standards while preserving the precise geometries created by laser cutting.

Medical Laser Cutting Services for Custom Needle Tubing

At HyTech Spring & Machine, our investment in state-of-the-art laser cutting systems, combined with rigorous quality control and advanced finishing processes, ensures that every hypotube we manufacture maintains the precision necessary for clinical excellence.

Whether your application demands the extreme flexibility of a neurovascular microcatheter, the balanced performance of a stent delivery system, or the rotational precision of a robotic surgical instrument, our laser-cut hypotube solutions deliver the technical performance your device requires.