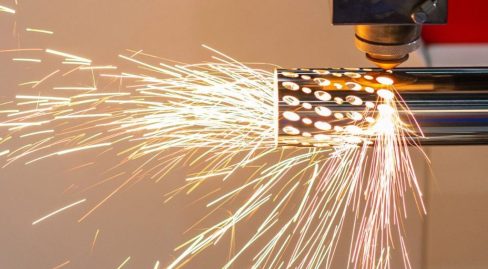

Medical-grade hypodermic tubing (or needle tubing) poses some unique manufacturing challenges. Imagine maintaining precision while producing complex cuts and end shapes on micro tubes as small as 0.009” outer diameter…while simultaneously meeting all the strict requirements that come with modern medical manufacturing.Luckily, compared to traditional machining methods, laser cutting has made the hypotube production process […]

News

Wire form manufacturing at the micron scale poses a number of unique challenges. As wire diameters shrink, precision tolerance control becomes increasingly crucial. Even the smallest variance can compromise the functional performance of the end product, if not render it entirely incompatible.At HyTech Spring & Machine, our micro wire form products typically involve precision components […]

Micro wire forms represent the intersection of precision engineering and medical innovation, enabling the minimally invasive procedures that define modern healthcare. At the micron scale, components must deliver uncompromising performance in flexibility, conductivity, and reliability while navigating the body’s most challenging anatomical pathways.From catheter reinforcement coils that resist kinking to nitinol guidewires that navigate complex […]

Small springs, miniature springs, and micro wireforms may only seem like minor parts in the grand scheme of things, but their design and performance are critical to the performance and reliability of exceptionally complex end products – including critical medical devices and aerospace components. The question many engineers and procurement teams face: should you use […]

For precision wire formed products, selecting the right material can be just as crucial as the product design itself. Different wire configurations (e.g. round vs. flat wire) as well as different materials (e.g. nitinol vs. music wire) can yield drastically different performance properties and product lifespans. At Hytech Spring & Machine, we specialize in custom-engineered […]

Material selection is just as critical as design and tolerances to ensure your small springs perform as expected. That’s especially true when the end application involves high performance, high stress, or exceptionally small-scale components – which is often the case for many of today’s high-tech aerospace and medical devices. Despite many more specialized alloy options, […]

Miniature and micro springs come in many different configurations. Essentially, the spring’s performance properties are determined by the coil and wire diameters, the wire material, as well as the actual shape of the wire itself. In terms of the latter, the choice typically comes down to round wire versus flat wire. The choice between round […]

Hypotubes (shorthand for “hypodermic needle tubing”) are extremely thin metal tubes which function as a shaft or reinforcement structure in modern medical applications. From extremely advanced neurovascular catheters to more common coronary procedures and drug delivery systems, high-precision hypotubes are critical components throughout today’s medical space. The Importance of Precision in Hypotube Manufacturing Hypotube components […]